It is a patented technology.

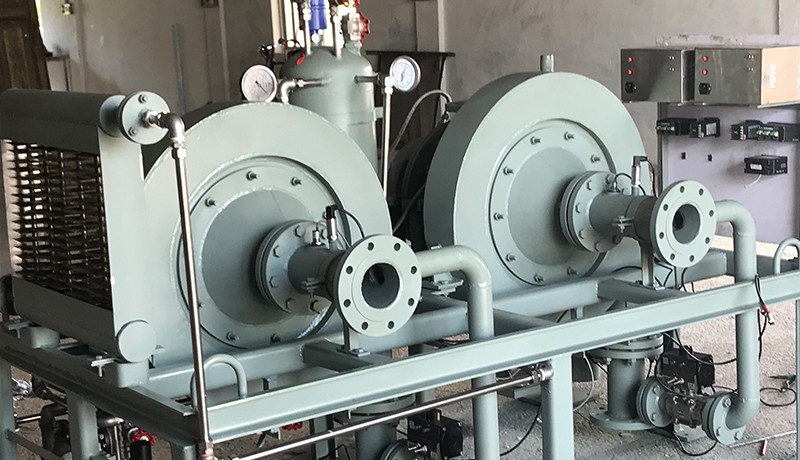

For the first time, small-scale installations can benefit from proven Organic Rankine Cycle (ORC) to capture wasted heat and turn it into additional power. The clean cycle system from EnerTek’s Heat Recovery Solutions division captures heat from a wide range of systems such as reciprocating engines, biomass boilers, microturbines and Concentrated Solar Power Unit.

The benefits

- Cleaner energy with no fuel needed

- No additional emissions

- Low-speed, high-efficiency power module

- Simple synchronization with utility

- Small-footprint packages unit: ready to integrate

- High reliability, very low maintenance and ownership costs

- Modular and scalable design

- Fast payback